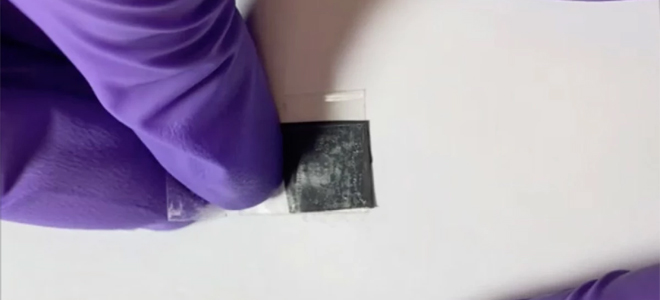

A team at UC Berkeley has developed a process that turns plastic waste into something more valuable – an adhesive. Based on an engineered catalyst, the inspiration was to find ways to “upcycle” plastics by putting them to new uses while preserving the properties that made them attractive in the first place.

Plastic waste is one of the modern world’s biggest environmental concerns, but plastics are notoriously unattractive to recycling companies. Unlike corrugated cardboard, glass, or scrap metal, plastics are very difficult to reuse and doing so makes the end product less valuable than the original plastic – which isn’t very valuable to begin with.

Plastics have a whole range of properties that are very carefully engineered into them, such as pliability, uniformity, and the ability to be processed with ease. They are also made so that they are not easily affected by chemical reactions. As a result, recycled plastics, such as polyethylene, often end up as low-value construction materials that have lost many of the properties of the original substance, or they are reduced to make fuels and lubricants, which are also low-value, environmentally questionable and have a short lifetime.

Polyethylene is the most common plastic in use today, with over 100 million tonnes of it produced around the world each year. In its many variants, it’s widely used in packaging, trash and grocery bags, geomembranes, agricultural mulch, toys, and various kinds of housewares.

newatlas